Electric Resistance welding is the process of joining metal pieces together by raising the temperature to fusion point by passing a strong electric current of high amperage and low voltage and applying the mechanical pressure to join them. In this process a strong electric AC current is passed through the metal pieces. This current comes across a certain resistance in passing from one pieces to the other which results in raising the temperature of the piece to the fusion or melting temperature and causes the pieces to weld together by applying the mechanical pressure at the junction.

Heat generated due to the resistance to the flow of current is expressed as H = IRT

where, H = Heat generated

I = Current flowing through the joint.

R = Resistance offered to the flow of current.

T = Time or duration of current flow.

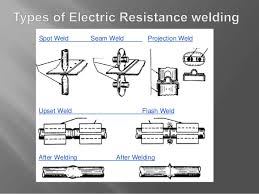

Electric Resistance welding has six types

1) Spot welding.

2) Butt welding.

3) Flash welding.

4) Seam welding.

5) Projection welding.

6) Percussion welding,