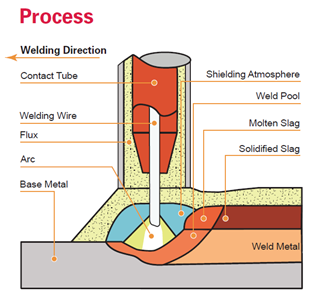

It is an arc welding process that uses an arc between a bare metal electrode and the weld pool.

The arc and molten metal are shielded by a blanket of granular flux on the work piece.

The process is used without pressure and with the filler metal from an electrode and sometimes from a supplementary source such as a welding rod, flux or flux with metal granules.

It is an automatic process developed primarily for the production of high quality butt welds in thicker steel plate than is normally suited to other manual arc welding processes.

As in open arc welding, the source of heat in the submerged arc welding process is an electric arc or arcs between a metal electrode or electrode and the work.

The welding zone is shielded by a blanket of flux, so that the arc is not visible. Hence, the name “submerged arc welding“.

The arc melts the parent metal, the electrode and the flux.

The fused flux produces a blanket of liquid slag which forms a protective envelope both around the arc and the welding zone. Right beneath the electrode tip a weld pool is formed, holding an amount of molten metal.

On melting, the electrode metal forms globules which go over into the puddle and mix with the molten parent metal, The pressure of the arc forces the mix out of the puddle so that it forms the weld.This action continues as long as the arc advances. The shape and size of the puddle have a strong effect on those of the weld.