Mixing : Thorough mixing of the materials is essential for the production of uniform concrete. The mixing should ensure that the mass becomes homogeneous, uniform in colour and consistency.

There are two methods adopted for mixing concrete :

(a) Hand mixing

(b) Machine mixing.

(a)Hand Mixing :- Hand mixing is practiced for small scale unimportant concrete works. As the mixing cannot be thorough and efficient, it is desirable to add 10 percent more cement to cater for the inferior concrete produced by this method. Hand mixing should be done over an impervious concrete or brick floor of sufficiently large size to take one bag of cement Spread out the measured quantity of coarse aggregate and fine aggregate in alternate layers. Pour the cement on the top of it, and mix them dry by a shovel, turning the mixture over and over again until uniformity of colour is achieved.

This uniform mixture is spread out in the thickness of about 20 cm. Water is taken in a water. can fitted with a rose-head and sprinkled over the mixture and simultaneously turned over. This operation is continued till such a time a good uniform, homogeneous concrete is obtained. It is of particular importance to see that the water is not poured but it is only sprinkled. Water in small quantity should be added towards the end of the mixing to get the just required consistency. At that stage, even a small quantity of water makes a difference,

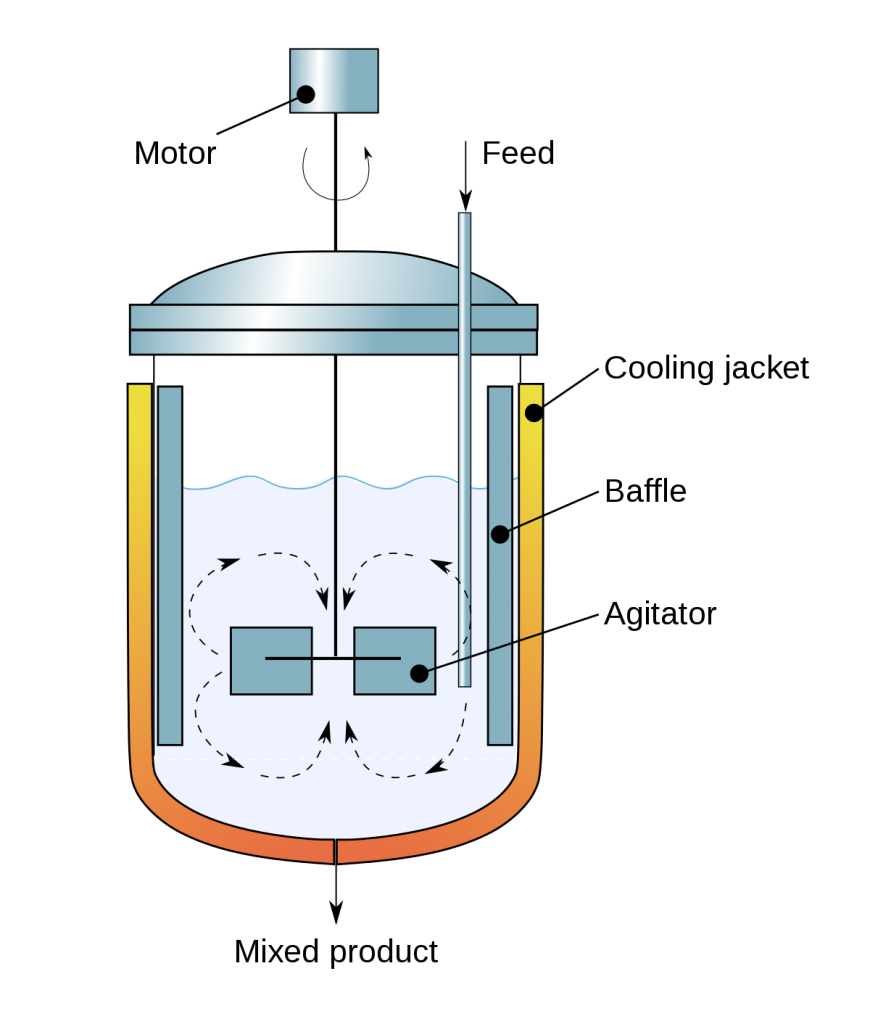

(b)Machine Mixing : Mixing of concrete is almost invariably carried out by machine, for reinforced concrete work and for medium or large scale mass concrete work. Machine mixing is not only efficient, but also economical, when the quantity of concrete to be produced is large Many types of mixers are available for mixing concrete.

They can be classified as batch-mixers and continuous mixers. Batch mixers produce concrete, batch by batch with time interval, whereas continuous mixers produce concrete continuously without stoppage till such a time as the plant is working. In this, materials are fed continuously by screw feeders and the materials are continuously mixed and continuously discharged. This type of mixers are used in large works such as dams. In normal concrete work, it is the batch mixers that are used. Batch mixer may be of pan type or drum type.

The drum type may be further classified as tilting or non-tilting or reversing or forced action type.

Are especially suitable for stiff and lean mixes, which present difficulties with most other types of mixers, mainly due to sticking of mortar in the drum. The shape of the drum, the angle and size of blades, the angle at which the drum is held, affect the efficiency of mixer. It is seen that tilting drum to some extent is more efficient than non-tilting drum.