Metal arc welding:

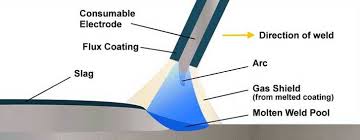

A metal rod of the same metal as being welded forms one of the electrode and also as a filler material. In this type of welding no separate filler rod is required

The arc is struck between the work being welded and the electrode which causes the melted rod to flow across the arc into the metal pool of parent metal.

Since, in case of bare metal arc welding, molten electrode wire and parent material are exposed to oxygen and nitrogen of the atmosphere and forms the oxide,

This reduces the ductility of weld and produces imbrittlement in the weld.

Therefore, the bare metal arc welding is preferred for unimportant works like metal deposition on railway wagon, wheels and travelling crane wheels.

For this type of welding. D.C. and A.C. supplies can be used

For DC supply. 50 – 60 volts are used for welding

But, mostly for current above 750 Amp, A.C. supply is preferred, as it is closely available, has high efficiency, negligible loss no load, minimum maintainance and less initial cost.

Welding transformer has the tappings on secondary to select required voltage for welding.

For AC supply 70-100 volts are used for welding