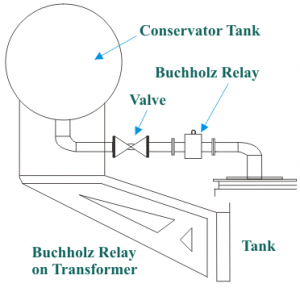

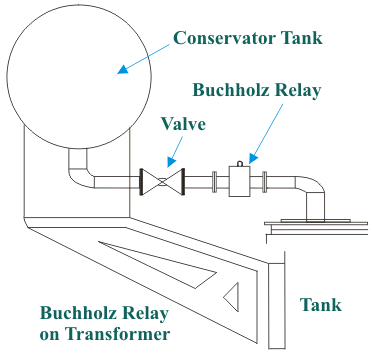

The buchholz (as/liquid operated) relay is connected in the pipework between the transformer tank and the conservator. If a valve is fitted to isolate the conservator, the buchholz relay is usually on the transformer tank side of the valve. Under normal conditions, the relay is full of oil.

Most faults occurring within oil filled transformers are accompanied by the generation of gas by the oil, due to liberation of heat. Such generated gas accumulates in the relay, thereby operating the float/flap switches. With an incipient fault, gas is produced at a very slow rate and the upper float (alarm) switch will operate after a specific volume of gas has accumulated.

The upper float (alarm) switch will also indicate the low oil level of the conservator. When a major fault occurs, the gas is produced rapidly, resuming in a sudden surge of oil up to the conservator, thereby operating the lower float(trip) switch

The lower load (trip) switch will also indicate the drained oil level of the conservator. To ensure successful operation of the relay, the pipe work on either side of the relay and the relay itself, are all set at the same angle ( 2° -3° to the horizontal for single float relay and 3° -7° to the horizontal for double float relay).

A machined surface is provided on the housing of the relay to check the oil level The arrow shown on the relay should point towards the conservator.