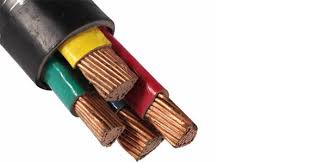

1.Radium -cured cables are manufactured in India by M/S Fort Gloster and are superior to steam- cured high, extra high and super tension cables. Were the cross linking is done by radium curing process instead of steam curing.

2. In any cross-linking process, the main factors which influence the quality of vulcanization are temperature, time and pressure parameters in any chemical reaction.

3. which are common The conventional steam cross-linking process uses mainly saturated steam for heating and pressurizing India for the dielectric.

4. In such a system, steam being at a comparatively high pressure (around 15 bar) and high temperature (about 200°C) diffuses into the cable insulation during the cross-linking process. Upon cooling, this diffused moisture supersaturated, and consequently condenses and forms micro-voids.

5. These micro-voids generally occur in the central region of the insulation wall. Radium cured cables are free from such voids and cavities.